CRAFTS

Leather Selection

METTIQUE selects only the highest quality real-grained leather for our products. We source our skins around the world, with an eye toward choosing the only the best skins of each type, from their respective places of origin across the globe.

When we select the leather for each pattern part, we quality-control all imperfections on the skins. And because we only use real-grained leather, a certain measure of natural imperfections from veins, or in the form of wrinkles, is natural and desirable. We treasure such patterns. However, in leather selection there is an aesthetic balance to be struck: between finding beautiful naturally occurring patterns and separating out imperfections so large they would distract from this beauty. With this balance in mind, it is the imperfections that are too noticeable that become “defects” by our standards. Therefore, all our skins are first thoroughly inspected, to ensure that only the finest parts are used. Our team spots, marks out and rejects any “defect” on the skins that do not meet our aesthetically driven quality standard. The craftsmen then select the area on the skin that is best suited for each pattern part.

CRAFTS

Process

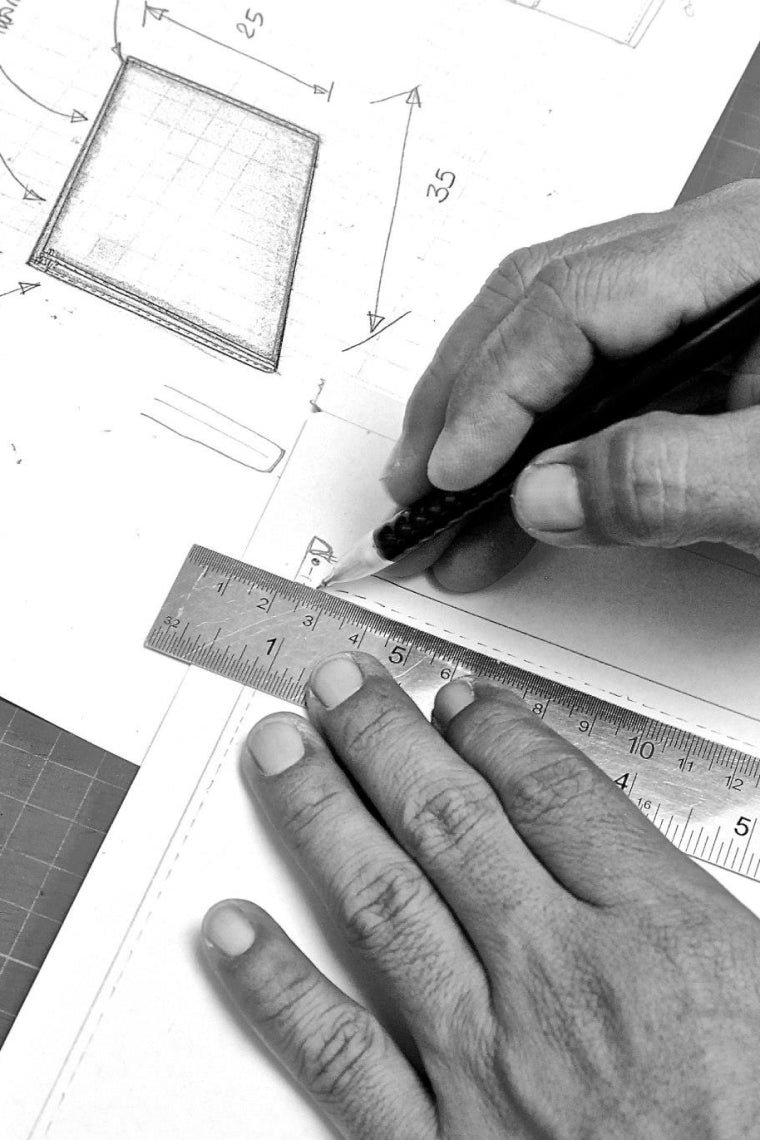

PATTERN MAKING

Before all patterns are made, each prospective METTIQUE piece of work is neatly hand-drafted in 3 dimensions on paper. Once finalized, our pattern makers accurately draw the patterns with the exact sizing on cardboard. The leather parts making up the final products are excised based on these cardboard patterns.

LEATHER CUTTING

The skins used for each pattern part are selected discerningly. We aim always to strike the proper balance: a uniformity and congruity of all parts, without sacrificing naturalness. We believe this is what results in a perfect end-product.

LEATHER THINNING

Each finished METTIQUE product of course comprises various pattern parts; some products are even composed of more than fifty pattern pieces. Each pattern part requires different thicknesses. Our leather fining specialists calibrate our fining machine with an accuracy on the scale of micrometers.

EDGE SKIVING

What distinguishes a METTIQUE piece of work from other products is that we pay attention to the smallest details. The precision crafting of distinguished pieces demands no less than master craftsmanship. We aim to hone our craft to a level of sophistication unmatched by other common ateliers. We craft some pattern parts by hand even after they have been thinned by machine. This provides us with a cutting accuracy of up to a tenth of a millimeter for pattern parts. The result is a precisely-crafted, well-proportioned final piece.

ASSEMBLY

Before the fined pattern pieces are stitched together, they must first be glued together. This is no simple process and is the all-important prerequisite to stitching. Only well-trained craftsmen can carry out a perfect gluing, ensuring the avoidance of excess glue that could damage the precious leather and endanger the assembly. Our craftsmen perform each assembly with skill, patience, and care.

HOLE PUNCHING

When a METTIQUE piece of work requires hand-stitching, holes are punched by our skillful craftsmen, who aim for perfect alignment every single time. Such an alignment is often overlooked in common ateliers, and this can result in flawed end-products. Proper alignment, though a detail, is the backbone of a perfect final stitching execution.

HAND STITCHING

METTIQUE is a modern atelier with a love of tradition, of craftsmanship, and of artisanship. In all cases, the best techniques are those that have been passed down through the ages, sometimes perfected over centuries. Hand-stitching technique lends an organic allure to a piece, and our craftsmen are masters of the hand-stitching technique. All of our work, which incorporates 100% hand-stitching, demonstrates a palpable artistry, an artisanal refinement, a charisma all its own.

EDGE POLISHING

All parts of each METTIQUE item are edge-polished to ensure high edge durability. All edge polishing steps are done entirely by hand. Once the edge in trimmed perfectly, the paint is then applied to the edge by hand very carefully to avoid any spills. METTIQUE selects only the best edge paints available in the market; ours come from Italy and France only. Once the edge paint dries up, the edge is then burnished, polished and buffed. This cycle is repeated a few times over and over until the perfect edge is achieved.

QUALITY CONTROL

Each METTIQUE product is quality controlled, by hand, by the craftsmen who make them. Piece by piece, they uphold our premium quality standard.

Read more

Our Values

Craftmanship

Leathers

Brand